Corrugated cardboard, a lightweight yet durable material, is a cornerstone of modern packaging. Its unique structure combines strength and cushioning, making it ideal for shipping boxes, displays, and protective partitions. Let’s explore how this versatile material is manufactured and the distinct roles of its outer layers: the liner and the medium.

The Production Process

1.Raw Material Preparation:

Corrugated cardboard starts with kraft paper, made from virgin or recycled wood pulp. Two types of paper are used:

– Linerboard: Smooth, sturdy sheets that form the outer layers.

– Medium: A thinner, fluted inner layer that provides cushioning and rigidity.

2.Corrugating the Medium:

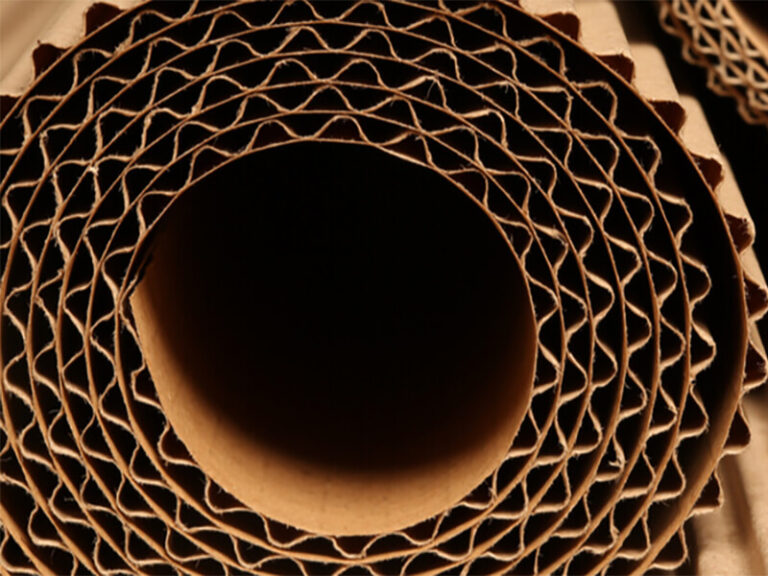

The medium is fed into a corrugating machine, where it passes through heated, grooved rollers. Steam softens the fibers, molding the paper into a wavy pattern (flutes). Common flute profiles include A, B, C, E, and F, each offering varying levels of thickness and compression resistance.

3.Adhesive Application:

Starch-based adhesive is applied to the peaks of the fluted medium. The linerboards are then pressed onto both sides of the fluted medium using heavy rollers, forming a single-wall corrugated board. For added strength, double- or triple-wall boards are created by adding more layers.

4.Drying and Cutting:

The bonded board passes through a drying section to cure the adhesive. It is then trimmed to size, scored, and slit into sheets ready for box fabrication.

Liner vs. Medium: Key Differences

While both layers are kraft paper, their roles and properties differ significantly:

1. Linerboard (Face and Back Liners)

– Function: Acts as the protective outer surface, providing smoothness for printing and resistance to abrasion, moisture, and punctures.

– Material: Typically made from high-quality, long-fiber kraft pulp for durability. The outer liner (face) often has a bleached or coated finish to enhance printability, while the inner liner (back) may be unbleached.

– Thickness: Thicker than the medium, ranging from 125 to 400 GSM (grams per square meter).

2.Corrugated Medium

– Function: Forms the fluted core, creating air pockets that absorb shocks and improve insulation. The flutes also add vertical compression strength.

– Material: Made from shorter fibers or recycled content, prioritizing flexibility over surface finish.

– Thickness: Lighter (80–180 GSM) but engineered to hold the flute shape during manufacturing.

Why the Distinction Matters

The liner’s smooth surface ensures branding clarity and damage resistance, while the medium’s fluted design maximizes structural integrity with minimal weight. This synergy allows corrugated cardboard to meet diverse needs—from delicate electronics packaging to heavy-duty shipping containers.

Sustainability in Focus

Modern production emphasizes eco-efficiency. Recycled fibers account for up to 70–100% of liner and medium content in many boards, and starch-based adhesives are biodegradable.

In summary, corrugated cardboard’s genius lies in its layered design. By combining robust liners with a resilient fluted core, it delivers unmatched practicality, sustainability, and cost-effectiveness—proving that simplicity in structure can yield extraordinary results.

How useful was this post?

Click on a star to rate it!

Average rating 0 / 5. Vote count: 0

No votes so far! Be the first to rate this post.