Packaging plays an important role in the manufacturing industry, ensuring the efficient and safe transportation of products. Among the many packaging solutions, carbon box have gained big popularity due to their cost-effectiveness, versatility, and environmental friendliness. To meet the increased demand for high-standard and timely packaging, every manufacturer needs a carton box gluing machine. This article explores the important reasons why a carton box gluing machine is vital for modern manufacturing processes.

1. What is a carton box gluing machine?

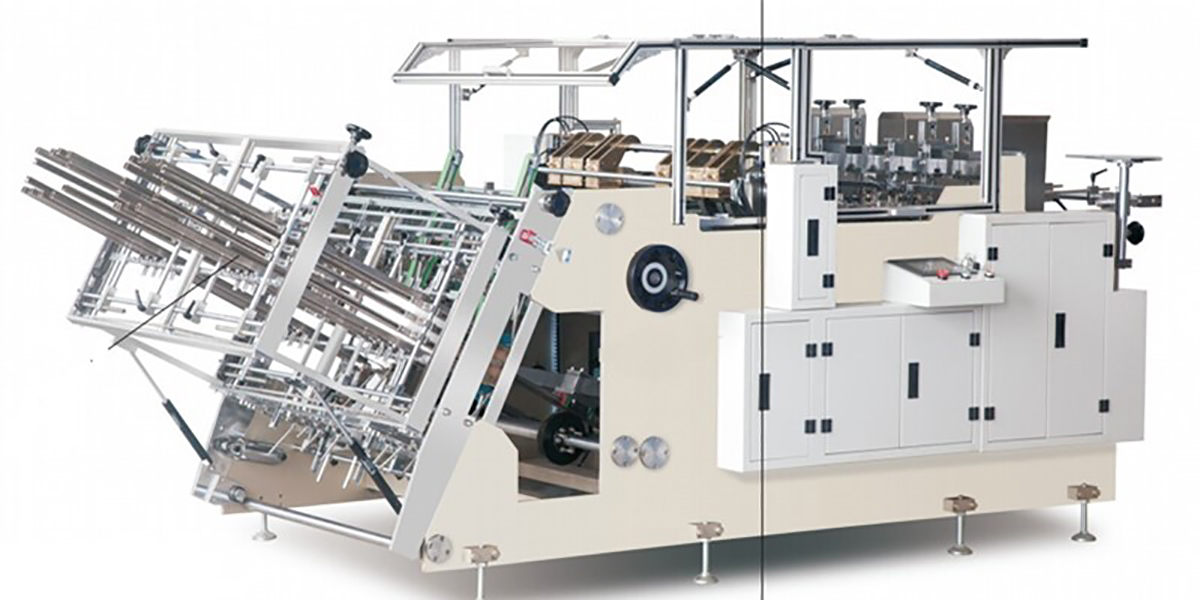

A carton box gluing machine is a piece of equipment used to apply adhesives to products or materials in a manufacturing or processing setting. This machine is designed to efficiently and rightly apply adhesive to surfaces such as cardboard, paper, or other materials, generally in a consistent and precise manner. Gluing machines are generally used in industries such as packaging, printing, woodworking, bookbinding, and woodworking to streamline the adhesive application process and ensure a high-standard finish.

General types of carbon box gluing machines used in the industry include top flap gluers, multi-point gluers, and side seam gluers, each designed for specific box styles and adhesive applications. For example, top flat gluers are best for sealing the top of boxes accurately and swiftly, while multi-point gluers are used for hard box designs requiring multiple glue points.

2. How does the box gluing machine work?

1. Machine components

The inner workings of a carton box gluing machine are masters of mechanical prowess. Key components include:

- Glue applicators: Specialized gadgets that dispense glue in controlled quantities and patterns.

- Conveyor system: A network of rollers or belts that transports the box blank through the gluing process.

- Compression and folding sections: Mechanisms that guide the blank into its right shape and apply pressure to ensure a secure bond.

- Drying system: A controlled atmosphere that permits the glue to harden and dry, ensuring optimal bonding.

2. Working principle

The working principle of the carton box gluing machine is that after the power is turned on, the full conveyor belt begins to move, the die-cut semi-finished carton is placed in the paper feeding position of the carton box gluing machine, and the one-box piece is mechanically set by the conveyor belt according to the paper stop head frame.

The good paper feed report is sent to the middle area of the belt (if the semi-finished carton is polished or coated and other surface treatments, after entering the middle area, the corresponding carton can be glued on the inside edge by a glue gun at the same time). The conveyor belt will transport the carton to the back area. The box-gluing part is pressurized and packed.

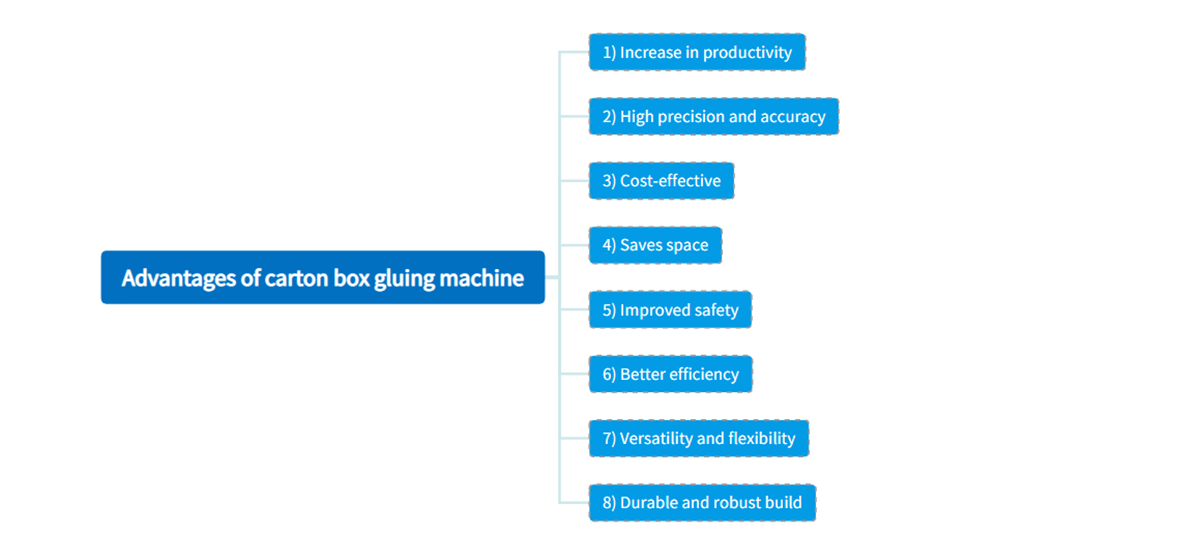

3. Advantages of carton box gluing machine

Here are some of the advantages of a carton box gluing machine:

1) Increase in productivity

An important advantage of carton box gluing machines is the prominent increase in productivity. Businesses see a surge in their output due to the top-speed operation of these machines. For example, a firm might double or even triple its output when they switch to a high-speed machine.

2) High precision and accuracy

High precision and accuracy an important advantages provided by these machines, including carton box gluing machines. They make sure that every carton is glued correctly, which stops waste and increases full product standards. Known machines, for example, are recognized for their precision and lowest error rates.

3) Cost-effective

Another benefit is that carton box gluing machines are cost-effective. The power efficiency spec contributes to this advantage. Lower power use means reduced operational costs, thereby making it an affordable solution for businesses.

4) Saves space

Carton box gluing machines help in saving areas in the production area. Given their compact design, these machines take up less room compared to traditional manual gluing techniques. This spec comes as a relief for many businesses struggling with restricted workspace.

5) Improved safety

Manual gluing involves the handling of adhesive, which can pose possible risks to workers. Exposure to adhesive contact or fumes with adhesives can cause skin or respiratory problems. A carton box gluing machine gets rid of these risks by automating the gluing process, decreasing employee exposure to risky materials. The machine also reduces the risk of accidents linked with manual gluing, such as burns or cuts.

6) Better efficiency

The mixture of increased productivity, reduced labor costs, and better product standards contribute to full efficiency gains for manufacturers. By streamlining the packaging process, producers can decrease lead times, better inventory management, and respond more successfully to market demands. A carton box gluing machine optimizes the packaging workflow and ensures a consistent workflow of high-standard packaging for timely product delivery.

7) Versatility and flexibility

Carton box gluing machines are designed to accommodate a wide range of carton shapes and sizes. This versatility permits producers to handle different packaging needs without investing in multiple machines. The machines can be simply adjusted to fit different carton dimensions, ensuring cost-effective and successful packaging for various products. The flexibility of carton box gluing machines permits manufacturers to meet the big packaging needs of their customers.

8) Durable and robust build

The durable and robust build of these machines makes them a remarkable asset. The machines are designed for long-term use, thus promising the best return on investment. These machines are built to last, making sure clients get the most value from their investments.

4. Disadvantages of carton box gluing machine

Here are some of the important disadvantages of the carton box gluing machine:

1. High cost

The price of a carton box gluing machine is very high, and the one-time investment is big, requiring the best financial support from the enterprise.

2. High power use

The carton box gluing machine uses a lot of power and has high operating costs, which is a big expense for enterprises with high power demands.

3. Difficulty in maintenance

The structure of the carton box gluing machine is very hard, and maintenance is quite difficult, requiring professional technical personnel to repair and maintain it.

4. High noise

The carton box gluing machine generates sufficient noise during operation, which has a certain impact on the hearing health of the professional staff.

5. How to install the carton box gluing machine

Before diving into box assembly using a carton box gluing machine, it is important to follow a systematic setup process to make sure perfect production. Begin by checking that the machine is free and clean from any previous adhesive residue, this can impact the standard of the glue application. Once the machine is fully clean, proceed to lead the right adhesive based on your box material and design features. For example, if you are working with corrugated cardboard boxes, go for an adhesive that gives a powerful bond perfect for this material.

Next, adjust the setting of the carton box gluing machine to get the right glue application. Take into account factors such as pressure, temperature, and speed to tailor the glue application process according to your specific needs. For example, when working with heavyweight boxes that need a powerful adhesive bond, consider raising the temperature slightly to make sure the right adhesion.

Additionally, adjusting the speed and pressure settings can help stop problems like uneven glue distribution or excess glue spillage during operation. Safety should forever be a high priority when setting up a gluing machine to avoid malfunctions or accidents that could upset production. Ensure all safety guards are in place and working correctly before starting the machine. Give training to operators on handling procedures and emergency protocols in case of unforeseen incidents.

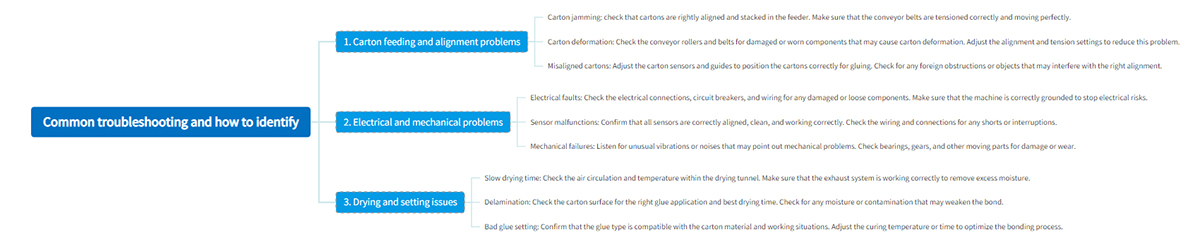

6. Common troubleshooting of carton box gluing machines and how to identify

1. Carton feeding and alignment problems

- Carton jamming: check that cartons are rightly aligned and stacked in the feeder. Make sure that the conveyor belts are tensioned correctly and moving perfectly.

- Carton deformation: Check the conveyor rollers and belts for damaged or worn components that may cause carton deformation. Adjust the alignment and tension settings to reduce this problem.

- Misaligned cartons: Adjust the carton sensors and guides to position the cartons correctly for gluing. Check for any foreign obstructions or objects that may interfere with the right alignment.

2. Electrical and mechanical problems

- Electrical faults: Check the electrical connections, circuit breakers, and wiring for any damaged or loose components. Make sure that the machine is correctly grounded to stop electrical risks.

- Sensor malfunctions: Confirm that all sensors are correctly aligned, clean, and working correctly. Check the wiring and connections for any shorts or interruptions.

- Mechanical failures: Listen for unusual vibrations or noises that may point out mechanical problems. Check bearings, gears, and other moving parts for damage or wear.

3. Drying and setting issues

- Slow drying time: Check the air circulation and temperature within the drying tunnel. Make sure that the exhaust system is working correctly to remove excess moisture.

- Delamination: Check the carton surface for the right glue application and best drying time. Check for any moisture or contamination that may weaken the bond.

- Bad glue setting: Confirm that the glue type is compatible with the carton material and working situations. Adjust the curing temperature or time to optimize the bonding process.

7. Maintenance of carton box gluing machine

- The repair and maintenance of the carton box gluing machine needs certain technicians to perform. Make sure the general operation of carton machinery and equipment to used, and plays a vital role and value in the production of cartons.

- Regularly check and change the lubricating oil in the gearbox of the paper-feeding part of the carton machinery.

- Regularly check the oil in the mechanical gear cover of the carton.

- Dirt on all friction areas, mainly adhesives or dust on the surface of each roller

- Disassemble and wash all rolling bears, and include new grease.

- Clean the sprocket and chain and refill the lubricating oil.

- If the chain is too loose, you can first adjust it by removing a few links, if it is extremely elongated, it should be changed. After the parts are assembled, paint can be added to the machine exterior if necessary.

- Check whether all the parts have been installed, then turn on the machine and observe whether the machine is working normally.

8. Carton box gluing machine FAQs

1. How carton box gluing machine is the best investment?

Investing in a carton box gluing machine delivers many benefits to businesses. Firstly, these machines significantly raise productivity, permitting quicker production rates and reduced labor costs. The automation of the carton box gluing process reduces the dependency on manual labor, permitting employees to focus on other jobs. Additionally, carton box gluing machines make sure consistency and precision in folding patterns, reducing rework and errors. This leads to better packaging standards and customer satisfaction.

2. What are the advanced functions of a carton box gluing machine?

Carton box gluing machines contain many important functions that better their efficiency and performance. These contain precise gluing mechanisms, adjustable speed controls, multiple creasing options, and fast changeover capabilities. Manufacturers generally integrate new features such as touchscreens, optical sensors, and programmable logic controllers (PLCs) to make sure optimal operation and ease of use.

3. What are the factors to consider when picking a carton box gluing machine?

Picking the best carton box gluing machine is important for businesses aiming to optimize their packaging process. Factors such as speed, machine size, maintenance requirements, folding capabilities, and after-sales support should be carefully evaluated. It is equally vital to consider the long-term suitability of the machine for the specific packaging needs of the business, as well as its compatibility with existing workflows and maintenance. By considering these factors, businesses can make the best decision, make sure the machine aligns with their requirements, and improve their packaging operations.

9. Conclusion

Picking the best carton box gluing machine is the best investment in your packaging efficiently. By carefully checking your needs and considering the factors outlined above, you can make the best decision that empowers your business to achieve packaging excellence. Remember, the best machine will elevate your operations and make sure that your box delivers your products with strong reliability.

How useful was this post?

Click on a star to rate it!

Average rating 5 / 5. Vote count: 2

No votes so far! Be the first to rate this post.

4 thoughts on “A Quick Guide for Carton Box Gluing Machine”

Pingback: anonymous

Pingback: anonymous

Pingback: دستگاه چسب زن کارتن سه موتوره چیست؟ | بررسی مزایا و 5 کاربرد

Pingback: اصول نگهداری و تعمیر دستگاه چسب زن کارتن + 6 عامل فرسایش آن