In the world of packaging, fanfold cardboard is a game-changer. It’s a versatile, cost-effective solution that’s reshaping the industry.

But what sets it apart from traditional cardboard sheets? This article will delve into the unique properties of fanfold cardboard. We’ll explore its benefits, uses, and how it compares to conventional cardboard sheets.

We’ll also touch on the machinery involved in its production, such as the Anybox box machine and other corrugated box making machines. Stay tuned to learn why fanfold cardboard is the future of packaging.

What is Fanfold Cardboard?

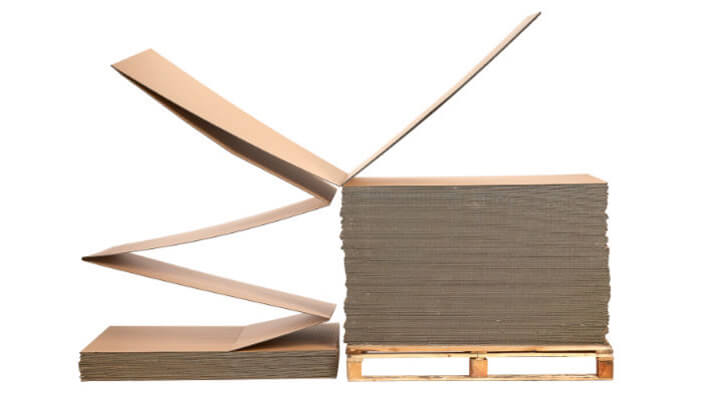

Fanfold cardboard is an innovative packaging material used widely today. Unlike traditional sheets, it comes in a continuous roll. This feature allows for seamless packaging without breaks.

The fanfold design enhances efficiency in packaging processes. Users can create custom-sized boxes, minimizing waste and ensuring better fit.

Fanfold corrugated cardboard is known for its strength and flexibility. It can withstand heavy loads while being adaptable to different shapes.

This type of cardboard streamlines operations in many industries. Businesses benefit from its ability to reduce handling time and costs.

Benefits of Using Fanfold Cardboard

Fanfold cardboard offers numerous advantages over traditional sheets. Its versatility makes it suitable for various packaging requirements. Companies can tailor packaging to exact needs, enhancing product protection.

The material is cost-effective due to its adaptability and ease of use. Businesses can save on storage costs because it requires less space.

Key Benefits:

- Customizable to fit diverse product shapes.

- Reduces waste and minimizes material usage.

- Saves on storage and handling costs.

- Environmentally friendly and recyclable.

Overall, fanfold cardboard improves efficiency and sustainability. It’s a smart choice for modern packaging solutions.

Fanfold Cardboard vs. Traditional Cardboard Sheets

Fanfold cardboard and traditional sheets each have unique benefits. Fanfold cardboard offers flexibility that traditional sheets cannot match. It adjusts effortlessly to different product sizes and shapes.

In contrast, traditional cardboard sheets are often limited by fixed dimensions. This can lead to wastage when products do not fit perfectly.

Fanfold cardboard reduces material waste significantly, as it aligns closely with required shapes. It also enhances packaging efficiency, cutting down on packaging time.

Overall, fanfold cardboard provides a more adaptable and economical solution. This makes it highly appealing to a wide range of industries.

The Role of Box Making Machines in Fanfold Cardboard Production

Box making machines are essential for producing fanfold cardboard efficiently. They streamline the cutting and shaping process. This increases the speed and consistency of production.

Advanced machines enable customization, ensuring the cardboard meets specific size requirements. These machines are integral to maintaining quality standards.

Furthermore, the precision of these machines reduces material wastage. This makes fanfold cardboard production not only efficient but also sustainable.

Anybox Box Machine: A Game Changer in Corrugated Box Making

The Anybox box machine revolutionizes how fanfold corrugated cardboard is produced. It offers incredible speed and accuracy. This enhances the overall packaging process significantly.

Its versatility allows for multiple box designs without frequent adjustments. This feature is crucial for businesses needing varied packaging solutions.

Moreover, this machine reduces labor costs by automating complex tasks. This efficiency makes it a valuable asset in the packaging industry.

Why Industries Prefer Fanfold Cardboard

Industries appreciate fanfold cardboard for its adaptability. It easily accommodates products of various shapes and sizes. This flexibility streamlines packaging operations.

Additionally, fanfold cardboard is eco-friendly and recyclable. It meets sustainability goals while maintaining efficient logistics and reduced waste.

Conclusion: The Future of Packaging with Fanfold Cardboard

Fanfold cardboard is transforming the packaging industry. Its flexibility, sustainability, and efficiency make it an ideal choice. Businesses are noticing its economic benefits, particularly in logistics.

With advancements in box making technology, like the Anybox box machine, fanfold cardboard’s potential is expanding. It offers a promising future for packaging solutions.

How useful was this post?

Click on a star to rate it!

Average rating 0 / 5. Vote count: 0

No votes so far! Be the first to rate this post.