The AOPACK BM2508-Pro is an on-demand box machine based on the previous model BM2508-Plus.

For several years, AOPACK has been collecting feedback from customers and partners around the world. Therefore, the BM2508-Pro is not just an improved model with a couple of minor changes, it is a model that inherits all the advantages of the BM2508-Plus and acquires fundamentally new features.

As standard, the machine is equipped with a glue gun and a built-in disk knife sharpener. All cutting and creasing knives have their own independent servo motors. Job changes that used to take 6 to 10 seconds now take 1 to 6 seconds. And thanks to changes in the design of the creasing wheels, the minimum creasing distance on the new model is 30 mm (standard).

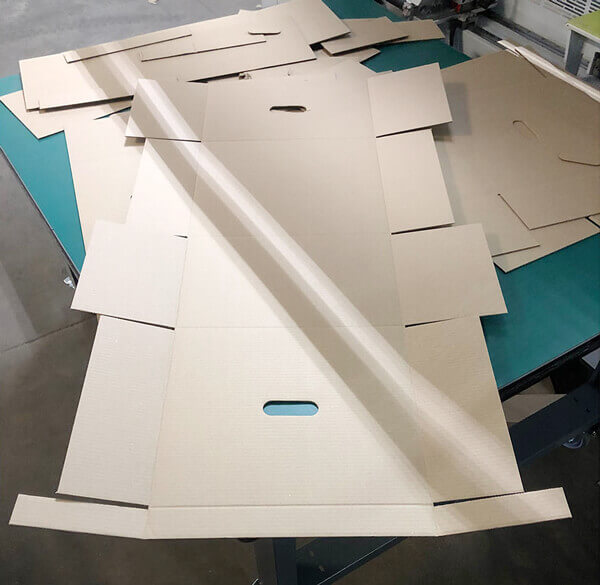

Complex orders, such as products with bends or holes, no longer require additional equipment and no additional process cycle. The BM2508-Pro can be equipped with a plotter cutting module, which allows cutting boxes of any configuration.

It is also possible to install a matrix cutting unit for cutting corners when producing 4-valve boxes.

The new generation model is characterized by even greater variability in the choice of thickness (from 2 to 12 mm) and type of corrugated cardboard. AOPACK BM2508-Pro works with sheet widths up to 2500 mm, minimum reamer size 200×650 mm.

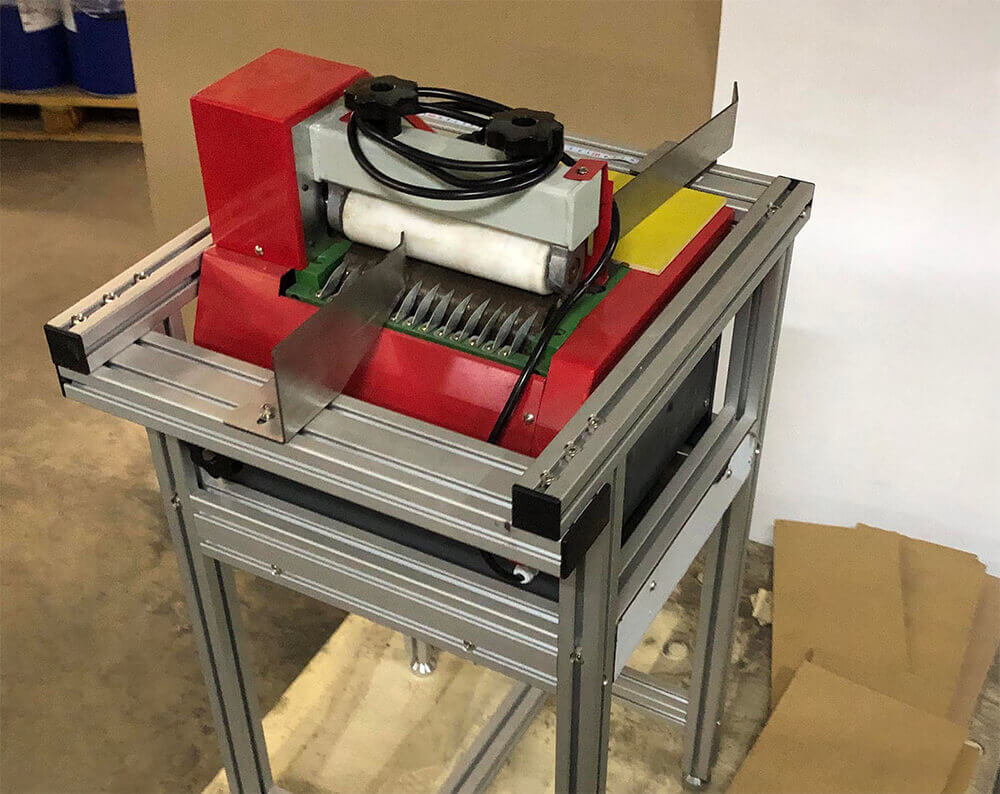

Together with AOPACK BM2508-Pro in LLC “Hoffromir” was installed semi-automatic machine for gluing with hot glue HMG-200, which allows to work with materials from 0.7 – 20 mm.

How useful was this post?

Click on a star to rate it!

Average rating 0 / 5. Vote count: 0

No votes so far! Be the first to rate this post.