The key components of the industrial equipment of these days are performance and accuracy. This is the point at which a container-making machine seems on the scene and absolutely transforms the packaging region. Globally, those machines have produced a faster option for bespoke packing containers and field packaging. Packaging answers that might be both versatile and efficient has become more and more vital as agencies grow and alternate. We assume the moment has come to speak about how using a box making gadget to make containers guarantees that items are effectively packed and prepared for the approaching cargo on planet shipping.

1. What is a box making machine?

A box-making system is a specialized piece of device designed to create boxes of various shapes and sizes efficaciously. These machines play a vital position in the packaging enterprise, permitting businesses to provide notable boxes in huge quantities with precision and speed. The introduction of container-making machines has revolutionized the packaging procedure, making it extra streamlined and cost-effective.

2. Working principle of box making machines

Understanding the operating precepts of field-making machines is crucial for maximizing their efficiency and making sure the production of splendid bins. These machines are engineered to automate and streamline the manner of container creation, offering consistency and precision. Let’s delve into how these machines’ characteristics, the key components worried, and the step-through-step method of field making.

Box making machines operate by using reworking flat sheets of material, such as corrugated cardboard or paperboard, into completely formed packing containers. This transformation entails a series of coordinated movements that cut, crease, fold, and glue the material into the favored field shape. The method is quite automated, lowering the want for manual labor and minimizing the danger of human errors.

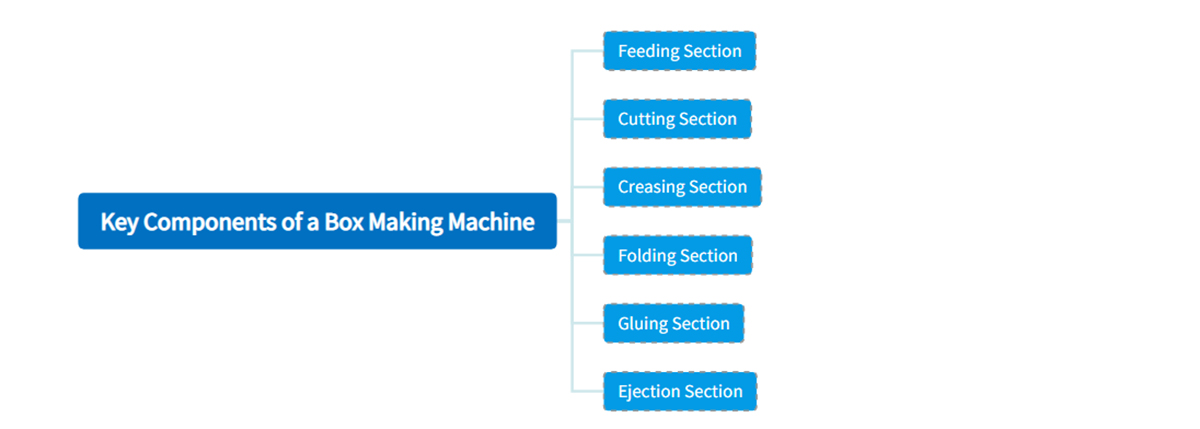

Key Components of a Box Making Machine

Feeding Section: This is where the raw material (usually in sheet shape) is fed into the machine. It can handle a stack of sheets, feeding them separately into the gadget for processing.

Cutting Section: Equipped with specific cutting equipment, this section is responsible for slicing the cloth into the favored shapes. This consists of growing slots, flaps, and edges required for the box structure.

Creasing Section: Here, the cloth is creased alongside the strains wherein it will be folded. This guarantees that the folds are easy and correct, that is crucial for the integrity of the box.

Folding Section: After cutting and creasing, the fabric moves to the folding section. Here, mechanical fingers and publications fold the material along the creased traces to form the field shape.

Gluing Section: In this phase, the adhesive is carried out to the important parts of the field. This may be done using hot softened glue, bloodless glue, or other adhesives relying on the material and box necessities.

Ejection Section: The very last phase of the device in which the completed containers are ejected from the gadget, ready for packing or in addition processing.

These key components require regular maintenance to keep your Box Making Machine performing at its best. So let’s talk about the importance and measures of maintaining the box making machine.

3. Types of box making machines

Box making machines are available in different types, every one designed to fulfill particular needs and programs. Understanding the various styles of field-making machines can assist businesses to pick out the proper system for their packaging necessities. Here are a number of the maximum commonplace types:

1) Corrugated box making machines

Corrugated field-making machines are the most broadly used within the packaging industry. These machines are designed to provide corrugated containers, that are made from corrugated cardboard. Corrugated cardboard consists of a fluted corrugated sheet sandwiched among flat linerboards. This production offers power and durability, making corrugated containers ideal for transporting and storing items.

Key Features:

- High Efficiency: Capable of producing big quantities of packing containers in a brief time.

- Versatility: Can create packing containers of diverse styles and sizes.

- Customization: Allows for printing and branding at the bins.

Applications:

- Shipping and Logistics: Widely used for transporting items.

- Retail Packaging: Ideal for packaging products for retail sale.

- E-trade: Commonly used for shipping objects bought online.

2) Rigid box making machines

Rigid container-making machines are designed to produce rigid containers, also referred to as setup boxes. These bins are made from thick paperboard and are recognized for his or her sturdiness and top-rate appearance. Unlike corrugated boxes, rigid containers are not collapsible and hold their form, providing superb protection for excessive-cost objects.

Key Features:

- Durability: Made from tremendous substances, offering superior safety.

- Luxury Appeal: Often used for high-stop merchandise because of their top-rate look and feel.

- Custom Finishes: Can be customized with diverse finishes, inclusive of embossing, foil stamping, and lamination.

Applications:

- Luxury Goods: Commonly used for packaging earrings, electronics, and different excessive-cost objects.

- Gift Boxes: Ideal for developing attractive present packaging.

- Retail Display: Often used for merchandise that requires a top-rate presentation in shops.

3) Folding carton box making machine

Folding carton container-making machines are designed to provide folding cartons, which can be crafted from paperboard. These boxes are lightweight and can be easily folded flat while no longer in use, making them handy for garage and transportation. Folding cartons are extensively utilized in numerous industries because of their versatility and cost-effectiveness.

Key Features:

- Flexibility: Can produce an extensive range of field styles and sizes.

- Ease of Use: Simple to gather and disassemble.

- Cost-Effective: Economical to supply, especially in massive portions.

Applications:

- Food and Beverage: Commonly used for packaging food items, beverages, and prescription drugs.

- Consumer Goods: Ideal for packaging cosmetics, electronics, and family gadgets.

- Retail Packaging: Widely used for retail products because of their versatility.

4. The box making process step-with the aid of-step

1. Material Feeding

The system starts off by feeding the raw fabric into the device. The feeding section ensures a continuous delivery of material, which is essential for maintaining manufacturing speed and efficiency.

2. Cutting

Once the fabric is fed into the gadget, it reaches the reducing segment. Here, the material is cut into particular shapes and sizes. High-precision cutting gear makes certain that each piece is the same, which is essential for the uniformity of the packing containers.

3. Creasing

Next, the cut material is transferred to the creasing section. Creasing involves developing indented traces wherein the material can be folded. This is carried out using creasing wheels or scoring equipment that follows stress alongside the exact fold lines.

4. Folding

After creasing, the fabric moves to the folding phase. Mechanical hands and guides fold the material alongside the creased traces, forming the simple structure of the container. This step calls for precision to make sure that every one edges and corners are aligned correctly.

5. Gluing

In the gluing section, the adhesive is applied to the essential flaps and edges. The type of glue used can vary, but it should offer a strong bond to maintain the field together. The device guarantees even software of glue to avoid any susceptible spots.

6. Ejection

The final step is the ejection of the finished container. The machine pushes the completed field out of the ejection segment, where it is able to be accumulated and packed for transport or storage.

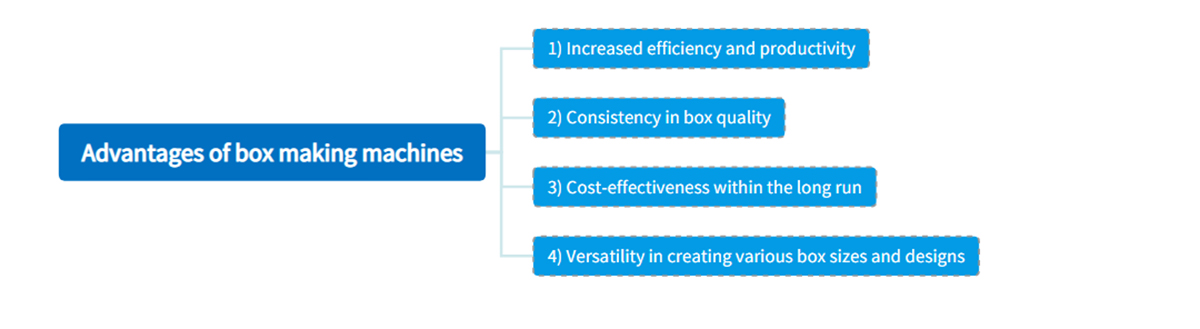

5. Advantages of box making machines

Box making machines have revolutionized the packaging industry, presenting numerous blessings that decorate efficiency, productivity, and common commercial enterprise performance. Here are the key advantages of using field-making machines:

1) Increased efficiency and productivity

One of the huge benefits of field-making machines is their capacity to dramatically boost efficiency and productiveness. These machines are designed to automate the field manufacturing system, significantly decreasing the time required to supply each container. Unlike manual techniques, which can be exertions-in-depth and time-eating, box making machines can produce huge portions of packing containers quickly and with minimal human intervention. This automation no longer simply hurries up manufacturing but additionally permits businesses to fulfill excessive calls without compromising on the best.

2) Consistency in box quality

Consistency is important in packaging because it ensures that every container meets the desired requirements and specifications. Box making machines excel in imparting uniformity throughout all bins produced. They are prepared with specific slicing and folding mechanisms that put off human mistakes, ensuring that each field is identical in length, form, and structural integrity. This consistency is critical for maintaining brand popularity and consumer satisfaction, as well-made boxes shield the goods effectively and present an expert picture.

3) Cost-effectiveness in the long run

While the preliminary funding in a field-making system can be vast, it proves to be value-powerful in the end. The automation and efficiency of those machines lessen the need for guide hard work, lowering operational prices. Additionally, the precision of field-making machines minimizes fabric waste, similarly cutting down costs. Over time, the savings on labor and materials, coupled with the increased production capacity, make box-making machines financially sound funding for organizations of all sizes.

4) Versatility in creating various box sizes and designs

Another wonderful gain of field-making machines is their versatility. These machines can be adjusted to provide boxes of different sizes and designs, catering to a wide variety of packaging desires. Whether a business requires small, elaborate containers for sensitive objects or massive, robust bins for bulkier merchandise, box-making machines can cope with it all. This flexibility allows agencies to diversify their product services and reply hastily to changing marketplace needs, giving them a competitive side.

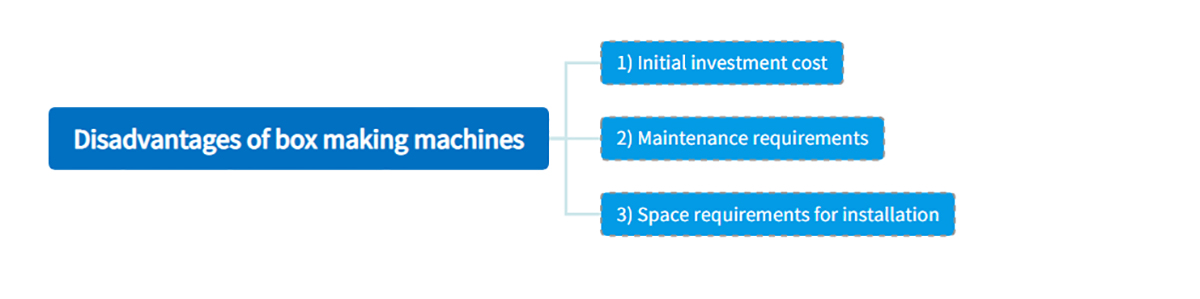

6. Disadvantages of box making machines

While box-making machines offer numerous advantages, it’s critical to consider their capacity drawbacks to make an informed decision. Here are the primary dangers related to these machines:

1) Initial investment cost

One of the most significant hazards of field-making machines is the excessive preliminary funding price. These machines can be high priced, in particular for small businesses or startups with constrained budgets. The fee varies depending on the type, length, and competencies of the machine. High-cease models with superior functions and better production capacities can be priced significantly higher. This sizeable premature rate may be a barrier for plenty of businesses, requiring careful monetary planning and consideration.

2) Maintenance requirements

Box making machines, like any industrial gadget, require everyday renovation to make sure ultimate performance and sturdiness. This requires specially trained personnel to maintain the machines, which can be difficult, increasing operational responsibility and costs.

3) Space requirements for installation

Another disadvantage of container-making machines is the huge area required for their installation and operation. These machines range in size, but many of them are large and cumbersome, necessitating enough floor area. Businesses operating in constrained spaces would possibly struggle to accommodate such gadgets without huge rearrangements or expansions. Additionally, proper installation frequently calls for specific environmental situations, together with solid flooring and adequate ventilation, similarly complicating the setup technique.

7. Box making machine FAQs

Box making machines are complex industrial tools that regularly spark numerous questions from capacity customers and industry experts. Below, we address a number of the most regularly requested questions that will help you better understand those machines and their abilities.

1) What types of boxes can be made?

Box making machines are extraordinarily versatile and may be used to produce an extensive form of packing containers to fulfill special desires. Here are a number of the most common sorts:

- Corrugated Boxes: These are the maximum usually produced boxes with the usage of container-making machines. They are widely used in delivery and packaging due to their sturdiness and power.

- Rigid Boxes: Often used for luxurious packaging, inflexible containers are sturdy and offer top-notch protection for excessive-stop products.

- Folding Cartons: These are used for customer goods packaging, consisting of cereal bins, cosmetics, and pharmaceuticals. They are lightweight and clean to keep.

- Die-Cut Boxes: These are custom-shaped containers, frequently used for specific or oddly-shaped merchandise. They are created with the usage of a selected die-cut process.

- Slotted Boxes: These are simple, value-effective bins often used for bulk packaging. They are clean to provide and require minimum fabric.

- Specialty Boxes: Depending on the customization skills of the box making device, various distinctiveness bins may be produced, including those with unique locking mechanisms, window cut-outs, and more.

2) How long does it take to set up the machine?

The setup time for a container-making system can vary drastically primarily based on the complexity of the machine and the consumer’s familiarity with it. Here’s a standard evaluation:

- Initial Setup: For a brand-new device, the initial setup can take numerous hours to 3 days. This includes unboxing, assembling the additives, calibrating the system, and jogging initial assessments to ensure the whole lot works efficiently.

- Daily Setup: On a daily foundation, putting in the gadget for operation typically takes between 30 minutes to an hour. This includes choosing and loading appropriate substances, adjusting the settings for the precise box type, and walking some take a look at runs to make certain accuracy.

- Changeover Time: If you need to replace from one kind of field to another, the changeover time can vary. Simple modifications can also take just a few minutes, whilst extra complicated changes may require up to an hour, particularly if distinct dies or settings want to be carried out.

3) What materials can be used with the machine?

Box making machines are designed to handle lots of materials to deal with unique packaging needs. Here are the maximum commonly used substances:

- Corrugated Cardboard: This is the number one cloth used in lots of container-making machines, especially for shipping and garage-packing containers. It gives strength and safety.

- Paperboard: Often used for folding cartons, paperboard is lightweight and may be effortlessly printed on, making it perfect for customer items packaging.

- Plastic: Some advanced container-making machines can handle plastic materials, which are used for durable and moisture-resistant packaging answers.

- Recycled Materials: Many machines can paint with recycled cardboard and paperboard, supporting environmentally-friendly packaging alternatives.

- Specialty Materials: Depending on the machine’s abilities, other materials together with laminated forums, metallic finishes, and lined papers can also be used for specialized packaging needs.

8. Conclusion

In the end, box-making machines are priceless gear inside the packaging enterprise, supplying a mix of performance, versatility, and precision. They are able to generate an extensive kind of containers, from strong corrugated delivery containers to elegant rigid bins for luxury gadgets.

How useful was this post?

Click on a star to rate it!

Average rating 5 / 5. Vote count: 1

No votes so far! Be the first to rate this post.