In today’s fast-paced manufacturing and packaging sectors, efficiency and precision are crucial. Carton erecting machines are key components in the production lines of countless industries. This article will delve into carton erecting machines, exploring their functions, working principles, and impact on various industries.

1. What is a Carton Erecting Machine

A carton erecting machine, also known as a carton former or case erector, is an automated device used to shape flat-packed cardboard boxes into their intended form. The machine takes flat carton blanks and folds, forms, and seals them to create boxes ready for immediate filling. Automation enhances overall production efficiency by saving time and labor.

2. Working principle of Carton Erecting Machines

Understanding what a carton erecting machine is provides a foundation for delving into its operational intricacies, which are crucial for optimizing packaging processes. Now, let’s explore the working principle of this innovative device to see how it works.

The carton erecting machine feed is generally divided into three entrances: manual entrance, material entrance, and package entrance.

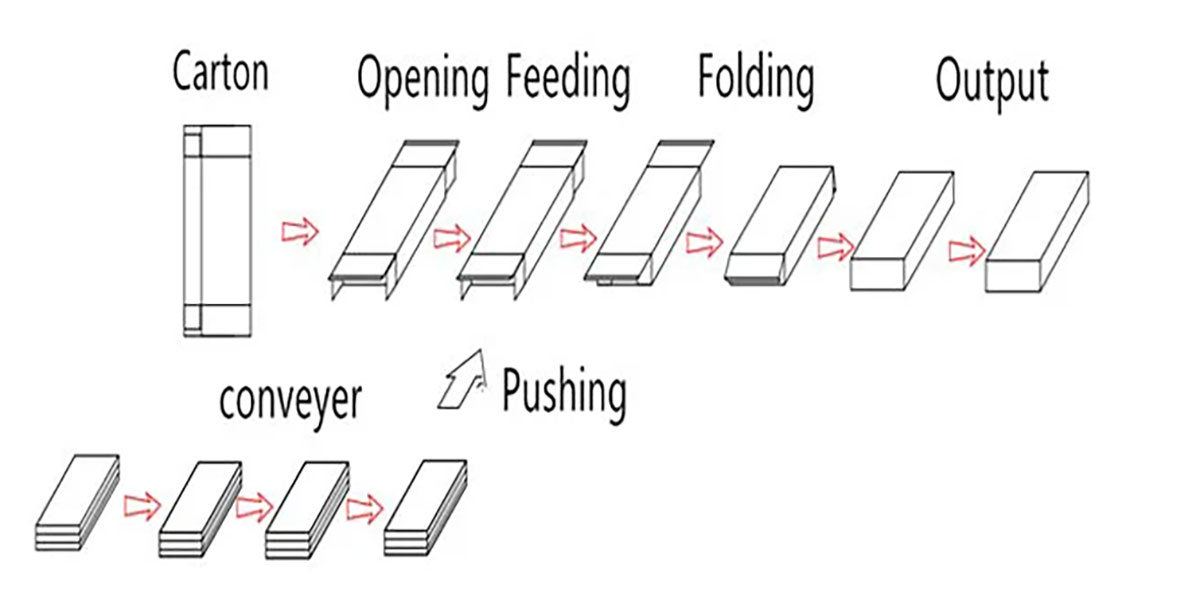

From machine-packing boxes to final packaging molding, the process can be roughly divided into four stages: unboxing, opening, filling, and closing.

In the first step, the carton is fed from the blanking device to the conveyor belt, and the machine transmits the command to the folding machine and the suction box.

Box suction devices are used to remove boxes from libraries and place them on moving rails.

The guide rail clamp fixes the carton, and the push plate opens it. As the carton moves forward to the filling area, two plywood pieces rise from either side of the guide rail to clamp the sides of the carton from front to back.

The conveyor belt of the carton erecting machine transports the materials, and the push rod pushes the materials into the empty boxes in the loading area.

Using the guide rail, the carton will enter the closing station once the material has been pushed into the box by the push rod. The mechanized system will first bend the tongue of the box, and the push plate will push the box cover to bend so that the tongue can be inserted into the box.

3. Advantages of Carton Erecting Machines

Utilizing carton erecting machines can offer numerous advantages to businesses, regardless of their industry. Here are some key benefits:

Increased Efficiency: Carton erecting machines operate at high speeds, significantly boosting the efficiency of the packaging process. In the long run, this leads to higher output and cost savings.

Improved Accuracy: Manual carton assembly is prone to errors, leading to material waste and additional labor costs. Carton erecting machines provide precision and consistency, reducing the likelihood of packaging mistakes.

Labor Savings: By automating the carton assembly process, businesses can reduce their reliance on manual labor, saving both time and money.

Enhanced Product Presentation: Carton erecting machines ensure that boxes are neatly folded and securely sealed, enhancing the overall appearance and presentation of products to consumers.

Sustainability: Packaging solutions that minimize material waste are available with some carton erecting machines. In today’s eco-conscious market, this is especially important.

4. Disadvantages of Carton Erecting Machines

Having explored the intricate workings of a carton erecting machine, it’s clear how its operational efficiency can transform packaging processes. Now, let’s delve into the advantages these machines offer, highlighting their impact on productivity, accuracy, and sustainability in various industries. Below are some disadvantages of the carton erecting machines.

1) It is expensive to build the entire machine in the initial stage because the cartons are expensive to acquire.

2) Increased production costs due to the cost of hiring additional personnel.

3) This machine is heavy and fragile, so there is no flexibility to move it after installation.

5. Maintenance of Carton Erecting Machines

While carton erecting machines offer numerous advantages, it’s important to consider the potential drawbacks they may present. Now that we’ve highlighted their benefits, let’s examine some of the disadvantages that businesses might encounter when implementing these machines. Following this, we’ll explore essential maintenance practices to ensure your carton erecting machine remains in optimal condition, maximizing its efficiency and lifespan.

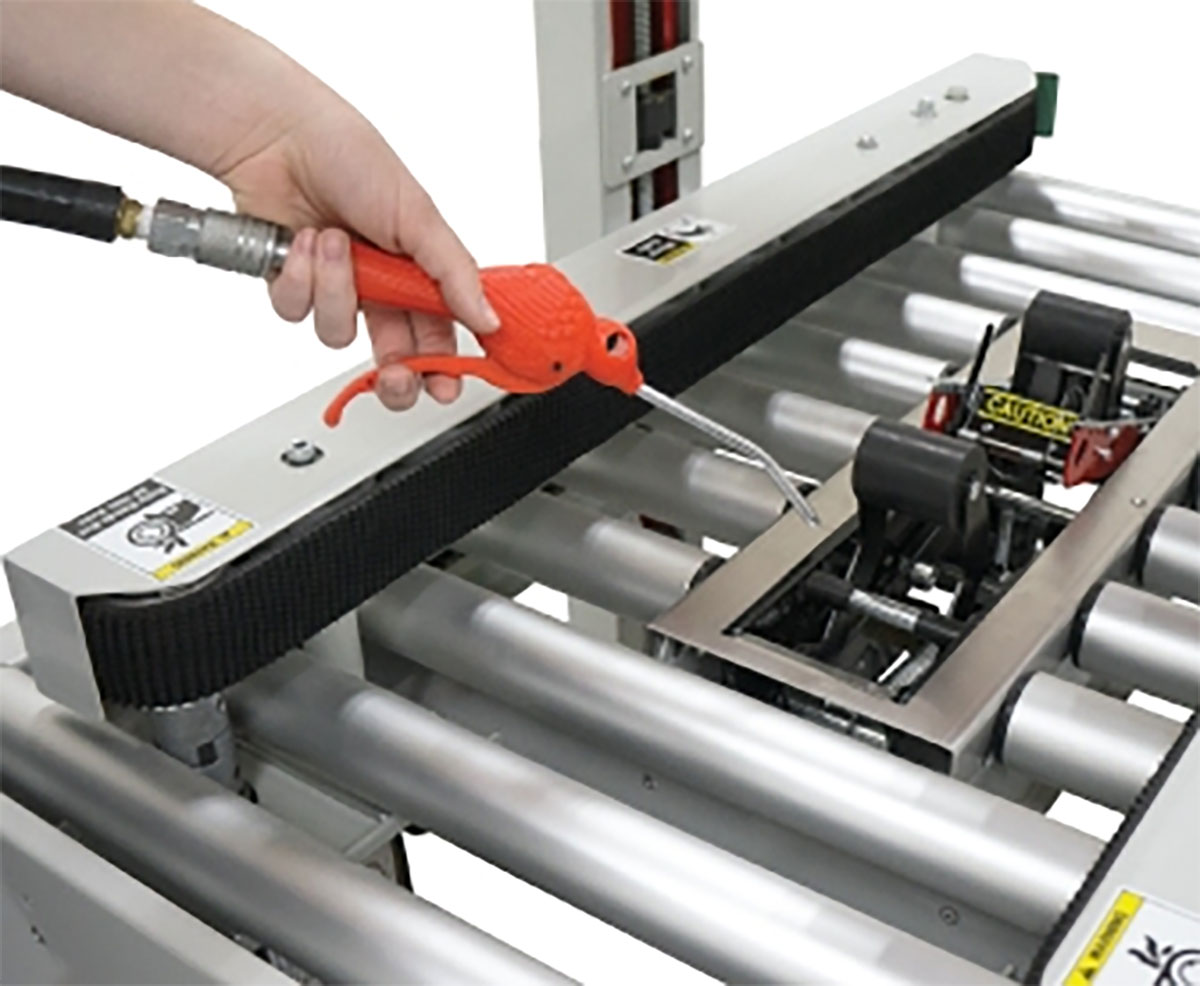

1) Maintaining cleanliness

Keeping the machine clean is crucial for its optimal performance. Ensure that dust, debris, and any residual packaging materials that may accumulate on the carton erector are regularly removed. This simple yet important practice not only prevents the buildup of contaminants but also helps you avoid potential malfunctions that could disrupt operations. Taking the time to maintain cleanliness will ensure your machine runs smoothly and efficiently.

2) Inspect for wear and tear

Over time, components of the carton erecting machine may begin to show signs of wear or damage due to continuous use and environmental factors. To ensure the machine operates smoothly, you must schedule routine inspections. Carefully examine each part for any wear, tear, or potential issues that could affect the machine’s performance. By identifying problems early, you can address them and replace worn parts before they escalate, further compromising your erector and business operations.

3) Train employees

Providing comprehensive training to machine operators is essential for maintaining equipment efficiency and reducing premature wear. Equipping your team with in-depth operational and maintenance knowledge can help keep your equipment performing for years. Regular and extensive training also empowers your team members with the necessary skills to drive your business forward and further optimize daily operations.

4) Stock spare parts

Maintaining a well-stocked inventory of spare parts is critical for minimizing downtime and costs during breakdowns. By regularly checking and replenishing spare parts inventory based on usage and anticipated needs, you can prevent delays in repairs. Having a well-organized spare parts system can be a strategic asset for smooth maintenance processes and uninterrupted workflows.

5) Lubricate the machine

Ensuring the smooth operation and longevity of the carton erector is vital. Regularly checking and lubricating all moving parts not only minimizes friction but also prevents wear and extends the equipment’s lifespan. This proactive maintenance practice can significantly reduce the risk of costly repairs and downtime, keeping your production line running efficiently.

By following these maintenance guidelines and caring for your carton erecting machine, you can ensure they operate at peak efficiency. With proper maintenance and care, you can extend the lifespan of your equipment, saving both time and money.

6. Troubleshooting of Carton Erecting Machines

When using a carton erecting machine, certain malfunctions may occur. To address common concerns, here is an introduction to some typical issues with carton erecting machines and their solutions:

Fault 1: The carton erecting machine packing machine absorbs vacuum from the cardboard box, and the vacuum time for the lower solid box is long enough?

Solution: In this step, we need to check each circuit, air circuit, solenoid valve, and vacuum generator, and adjust the parameters accordingly.

Fault 2: When the carton erecting machine is working, does the rising cylinder of the lower solid box not move or does it move very slowly?

Solution: It is necessary to accelerate the cylinder regulating valve, and if it is not possible, replace the solenoid valve.

Fault 3: Insufficient air pressure, damaged suction cup, or malfunctioning suction cup.

Solution: Replace with a new product or adjust the air pressure.

Fault 4: Abnormal tape applicator

1) The tape cuts continuously.

Solution: The blade is no longer sharp or the tape film is stuck at the blade tip. Replace the blade, wipe it clean, and apply oil.

2) The tape has been cut but dragged one section.

Solution: In addition, the knife holder is stuck, and the action is not flexible or the spring is not tight enough. Check the screws at various parts of the tape applicator or adjust the tension of the tension spring.

3) The tape was cut but did not adhere to the box surface.

Solution: The main tension spring is too loose, and the rebound speed of the rear wheel cannot match the belt speed. Moderately tighten the main tension spring screw.

4) The cardboard box got stuck in the middle.

Solution: The main tension spring is too tight and the front wheel is stuck in the middle. Moderately loosen the main tension spring of the belt wheel.

5) The tape is prone to detachment.

Solution: If the one-way roller loses its effectiveness, replace it with a new one-way roller.

7. Carton Erecting Machines FAQS

Q1: How easy is it to adjust a carton erecting machine from onecase size setting to the next?

A1: Carton erecting machines are designed to be simple to operate with quick and easy case size change. The controls are simple and operator friendly and full training will be given at the time of installation. It typically takes between one and five minutes for a full size change.

Q2: Can carton erecting machines handle cases of variable quality?

A2: Yes, this is a specific area of strength due to the features included in case erecting machines.

Q3: Can carton erecting machines deal with specialist cases for shelf-ready?

A3: Yes, in many situations they can handle cut-outs and perforations as well as non-standard flap designs.

8. Conclusion

In conclusion, carton erecting machines are invaluable assets in the world of manufacturing and packaging. Their versatility, precision, and efficiency make them indispensable in various industries, from food and beverage to e-commerce and pharmaceuticals. As technology continues to evolve, carton erecting machines are likely to become even more integral to the packaging process, ensuring that products reach consumers in perfect condition.

How useful was this post?

Click on a star to rate it!

Average rating 0 / 5. Vote count: 0

No votes so far! Be the first to rate this post.