Packaging plays a crucial role in your business when bringing your products to the market. The process is carried out by packaging machines, which come in two main types based on their level of automation: automated and semi-automatic machines. With various options available, it can be challenging to select the best packer for your production needs. This article compares semi-automatic packers to automatic packers and guides you through the process of choosing the most suitable packer for your production line.

1. Semi-Automatic VS. Automatic Packer: Overview

Let’s start with an overview. To choose between semi-automatic and automatic packers, consider several factors. These include the type of packaging machine needed, the kind of products (such as powder, granule, or liquid), and your desire to increase efficiency or save on labor and materials. This decision will also be influenced by your budget. Understand how much you want to invest to achieve the required return on investment.

Automatic machines often have better production efficiency because they use advanced technology. They also save a lot of labor as they don’t require a full-time operator. In contrast, semi-automatic machines need an operator. However, if your products come in many different configurations, a semi-automatic packer might be more cost-effective.

If you have a small business with a limited budget, multiple semi-automatic machines could be a cheaper alternative to a fully automatic machine. These machines are also quite self-contained once started, making them good for limited, high-production products.

2. Semi-Automatic Packers — Advantages & Disadvantages

Now, let’s dive into semi-automatic packers. A semi-automatic packer partially automates your packing process. It utilizes a modernized packing process to optimize the efficiency, ergonomy, and productivity of your case-packing process. Semi-automatic packers include at least one automated feature. This means that a semi-auto packer’s packing person/operator remains the key factor of the packing process but with the help of at least one auto function.

1) Advantages of Semi-Automatic Packers

These packers are economical, simple, and versatile. They can double your packing speed, making the packing process four times faster per person.

(1) Quick and Easy Installation & Setup

Moving from no-automation to semi-automation brings along many benefits. One of the major advantages is that semi-automatic packers are quicker and easier to install & set up relative to fully-automatic packers.

Using semi-automatic packers is the first step towards semi-automation, unlike the traditional manual packing process that’s used with collecting tables. Some semi-automatic packers’ setup time is as short as 5 minutes.

Being economical, simple, and highly versatile, semi-automatic packers can help double your packing speed with only 1 packing person (instead of 2 packing people) thus making the packing speed per person more than 4 times faster.

(2) More Flexibility and Quality Control

The degree of flexibility offered by a semi-auto packer may also be one of its biggest selling points. By installing a semi-auto packer on your folder-gluer, you give your packing staff the power of easy access that allows them to make adjustments, quality control checks, and corrections without ever needing to interrupt production.

2) Disadvantages of Semi-Automatic Packers

However, semi-automatic packers are not perfect. They have some disadvantages.

(1) Not the Top Speed

While having easy access and the capability to conduct quality control checks can be beneficial if required, it’s essential to be aware of the trade-offs. The increased access and adjustability may result in slower processing speeds. Additionally, human supervision is still necessary. In regions facing labor shortages or increasing wage costs, the benefits of this option may not outweigh the drawbacks. It’s crucial to weigh these factors carefully when considering the best approach for your operations.

(2) Varying Productivity

With the demand soaring for unconventional boxes that come in various sizes and shapes and their own inconveniences, adapting to the complex needs of the market has become more important than ever. The productivity of your folder gluer can vary significantly depending on the types of boxes you manufacture and the strategies you employ to enhance output. By optimizing your production processes and implementing efficient techniques, you can achieve substantial improvements in productivity levels.

A semi-auto packer is highly versatile and flexible, so there are so many things you can do to push your folder to its maximum potential. Indeed, there are numerous factors that can lead to productivity losses and bottlenecks in your folding-gluing operations. That’s why maximizing the effectiveness of your semi-automatic packer training is crucial. By ensuring that your team is well-trained and equipped with the necessary skills, you can mitigate potential issues and optimize the performance of your packaging processes.

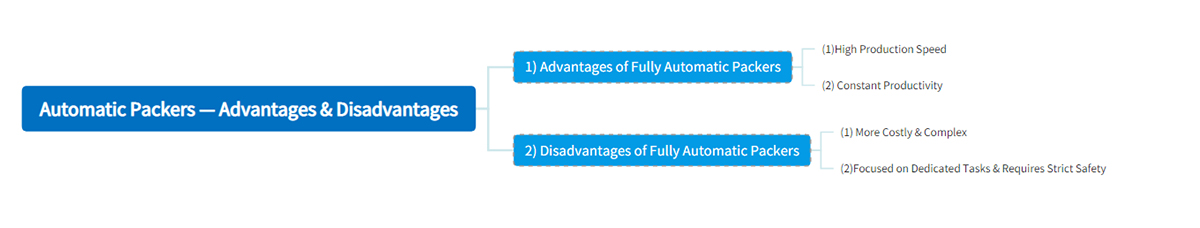

3. Automatic Packers — Advantages & Disadvantages

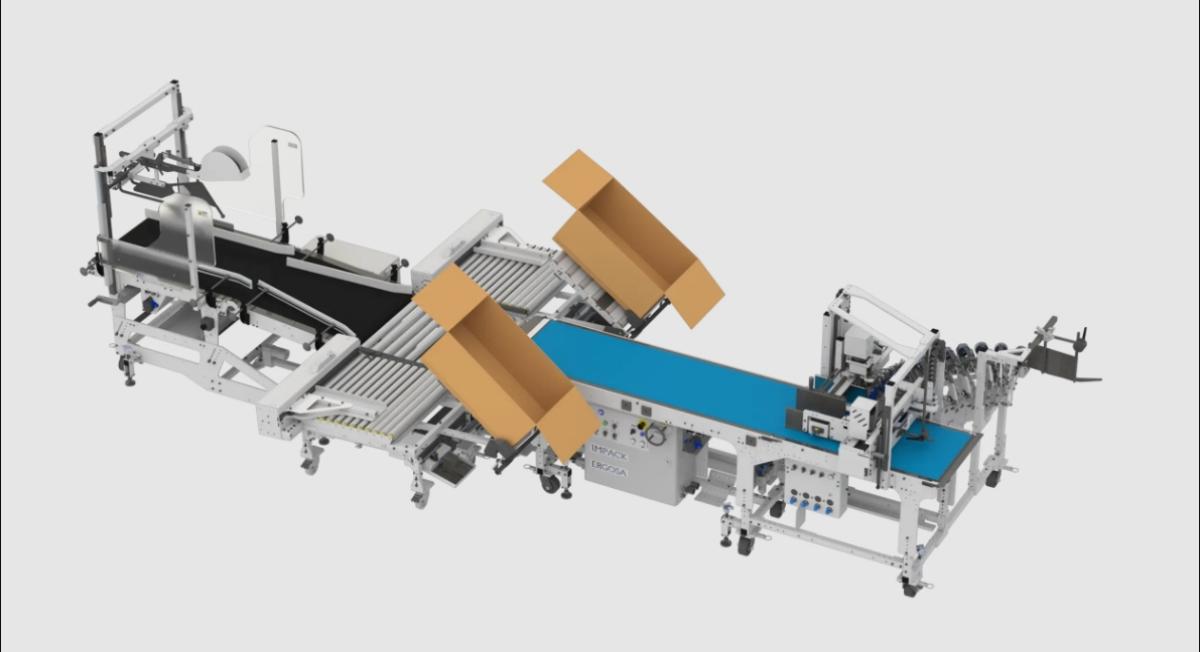

Let’s move on to automatic packers. In terms of automation, an automatic packer offers the highest level of efficiency. It is when you’ve automated your entire packing process so that the operator is no longer required to be present.

When it comes to comparing collecting tables vs. semi-auto packers vs. automatic packers, it is easy to see why clients prefer fully automated packers.

Automation offers advanced capabilities and efficiency, but it also comes with complexities such as the requirement for digital expertise, a larger physical space, and higher costs. Despite these challenges, for certain companies, full automation may be the most practical and beneficial choice to meet their production needs effectively.

1) Advantages of Fully Automatic Packers

Semi-automatic packers offer a high level of versatility and flexibility compared to automatic packers. Known for their adaptability, they are a popular choice among many businesses. However, it’s crucial to assess your company’s specific needs and circumstances. Fully automated packers excel in situations where extreme productivity is essential, especially when demand is rapidly growing or when labor resources are limited. Choosing the right packer depends on understanding your production requirements and aligning them with the capabilities of each type of machine.

(1)High Production Speed

Automatic packers have the advantage of high production speed. If your typical production is one-row, one-layer — medium to large boxes — with an extreme focus on speed, then full automation with such automatic packers might be the perfect fit.

Some of them have a speed of up to 8 cases per minute, with a high-precision laser counter, and on a small footprint. However, if your typical production is multi-row, multi-layer case packing, then they might not be the right fit for you.

(2) Constant Productivity

Automatic packers take no breaks and no vacations. Operating 24/7, the capabilities of those machines are unmatched. For companies handling substantial volumes of folding cartons or laminated boards with standardized box sizes, maintaining consistent productivity is paramount. With such high production numbers, ensuring efficiency and reliability in your packaging processes becomes essential for the success of your operations.

Automatic packers are the only viable option when consistency and speed are required.

2) Disadvantages of Fully Automatic Packers

Packaging processes require some level of centralization to be automated. While this usually is advantageous in terms of space allocation and efficiency, make sure your operation can adapt to a new, centralized configuration.

(1) More Costly & Complex

Automatic packers require a very precise and technical installation process, so their one-time cost is higher. Plus, they are more limited in terms of what they can do.

(2)Focused on Dedicated Tasks & Requires Strict Safety

A semi-automatic packer provides you with the flexibility to process various box sizes through your folder-gluer. By having easy access to boxes and the ability to manually handle them and place them into cases, you are able to adapt to different packaging requirements easily and effectively.

In contrast, when it comes to a fully automatic packer, you need a larger footprint. Your automatic packer has to be 100% safe. As a result, in case of a problem, the system has to be shut down to zero with an emergency stop, otherwise, a human being would be at risk.

4. Which Packer Should You Choose?

When it comes to choosing between a semi-automatic packer and a fully automatic packer, there is no one-size-fits-all answer. The decision ultimately depends on your company’s unique requirements, circumstances, and objectives. It’s essential to evaluate your production needs carefully to determine which type of packer aligns best with your goals. That’s not all I have to say. Here is the answer you’ve been looking for:

1) A Manual Packing Help/Aid is Best When:

- You need to take the first step to improve the productivity of your folder-gluer

- You’re not sure of your production and have a very tight budget

- You have complex boxes that need constant adjustments/quality control checks

- You have very limited floor space

If your production meets several of the characteristics described above and you’ve never had any “packing help” or “packing aid,” then a collecting table could be an excellent start.

2) A Semi-Automatic Packer is Best When:

- You have variable production runs

- You have small to medium-sized boxes

- You have a wide and various variety of box formats

- You have complex boxes that need constant adjustments/quality control checks

3) An Automatic Packer is Best When:

- You have long production runs

- You have medium to very large-sized boxes

- You are constrained by a limited variety of box formats that are similar in nature

- You have uncomplicated boxes that require minimal adjustments and quality control checks

4) An Automatic Packer is Best When:

- You possess all the automatic packer requirements detailed above

- You aim to completely automate your packing process

- You desire to achieve a fully automated operation with zero human involvement

- You have a keen interest in advanced monitoring and Industry 4.0 functionalities

I’m glad to hear that you found the information helpful in guiding your decision-making process for selecting the right folder-gluer packer. Feel free to reach out if you have any more questions or need further assistance. Making informed choices is key to optimizing your packaging operations for success.

5. Conclusion

When deciding between an automatic packing machine and a semi-automatic packing machine, it’s essential to weigh the advantages and disadvantages of each. While the fully automatic option may come with a higher price tag, it offers efficiency and reduced manual intervention. On the other hand, the semi-automatic machine provides flexibility but may require some manual assistance. Ultimately, the choice depends on your budget and specific production needs. If budget allows, opting for the automatic machine can streamline operations. Otherwise, the semi-automatic machine with manual support can still enhance production efficiency.

How useful was this post?

Click on a star to rate it!

Average rating 0 / 5. Vote count: 0

No votes so far! Be the first to rate this post.