Are you an entrepreneur with experience in commercial packaging and the paper industry? If so, starting a small-scale corrugated box manufacturing plant could be the perfect business opportunity for you. Whether you’re based in a bustling city or a quieter suburb, this business can thrive anywhere. Every manufacturing business, big or small, relies on boxes to package their products. A well-designed and sturdy box is essential for delivering goods to customers. Many aspiring entrepreneurs are interested in entering the box manufacturing industry but may lack knowledge about setting up a corrugated box plant.

Today, we’ll discuss the common challenges faced when establishing a corrugated box manufacturing plant. This information aims to assist equipment buyers and individuals planning to launch their own carton factory.

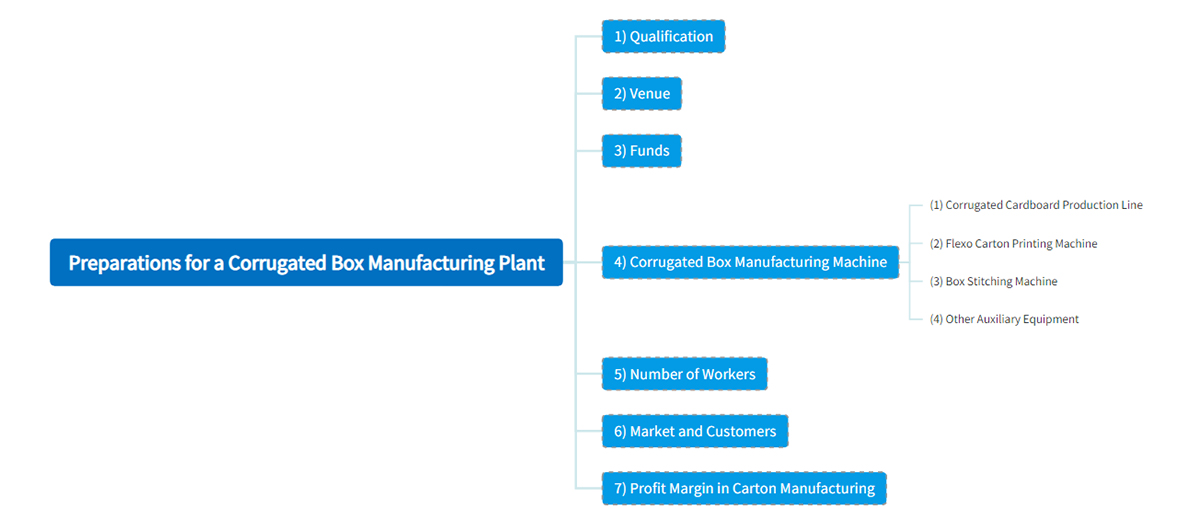

1. Preparations for a Corrugated Box Manufacturing Plant

When planning to establish a new corrugated box manufacturing plant, it’s crucial to consider the following points in the planning process. These factors are essential for ensuring a successful setup and operation of your manufacturing facility.

1) Qualification

To kickstart your corrugated box manufacturing plant, the first step is to obtain the necessary qualifications and documents. Here’s what you need to do:

- Visit the Industrial and Commercial Office to apply for an industrial and commercial business license;

- Head to the Health Bureau of the Ministry of Environmental Protection to secure a health permit;

- Approach the Taxation Bureau to obtain a tax registration certificate;

- Ensure you have all other qualification documents as per local laws and regulations.

2) Venue

When selecting a location for your corrugated box manufacturing plant, opt for a site with easy access to transportation, preferably within or near an industrial park. This choice not only facilitates business expansion but also helps in cutting down transportation expenses. The space requirements vary based on your operations:

- For plants that purchase cardboard and process semi-finished products, around 300-600 square meters are needed.

- If cardboard production is part of your operations, a larger area is necessary.

- Allocate separate storage areas for raw materials, semi-finished, and finished products.

For a semi-automatic plant, a minimum of 5,000 square feet is required, while an automatic plant needs at least 30,000 square feet. The area specifications can be adjusted according to production capacity.

3) Funds

To establish a corrugated box manufacturing plant, you’ll need to allocate funds for various expenses, including:

- Factory rent (if not self-owned)

- Machinery and equipment costs for carton production

- Raw material expenses

- Employee wages

- Management expenses

- Working capital, and more.

4) Corrugated Box Manufacturing Machine

To begin the manufacturing process, the following machines are needed:

(1) Corrugated Cardboard Production Line

Choose from 2/3/5/7 layer corrugated cardboard production lines, priced based on speed and cardboard width.

(2) Flexo Carton Printing Machine

Invest in a printing slotting machine or printing die-cutting machine, available in manual, semi-automatic, and fully automatic options. While automatic machines offer excellent printing quality and speed without manual intervention, manual machines are more budget-friendly but require manual operation.

(3) Box Stitching Machine

For carton forming, you’ll need a box stitching machine or a box folder gluer, available in manual, semi-automatic, and fully automatic variants. Manual box staplers are cost-effective, while box folder gluers are pricier but offer efficient gluing capabilities.

(4) Other Auxiliary Equipment:

- Paper separator or thin knife machine: Cut the cardboard into required sizes. Consider precision and cost when choosing between the two.

- Flat creasing machine: Produces high-precision cartons.

- Packing machine: Bundles formed cartons for easy transportation and stacking.

Additional equipment like stacking machines, flute laminating machines, and more can be purchased based on specific production needs.

5) Number of Workers

To meet production requirements, you’ll need a skilled team including a printing press master, paper delivery master, nail box master, packing master, and general workers. Skilled technicians, especially printing masters, play a crucial role in enhancing work efficiency, plate placement speed, and print quality. Additionally, a small sales team is essential to kickstart sales efforts, generate revenue, and establish a strong market presence swiftly.

6) Market and Customers

During the initial stages of setting up your corrugated box manufacturing plant, focus on attracting customers with competitive pricing. Gradually build customer relationships through excellent service and consistent quality. Once your operations stabilize, prioritize customers who pay promptly, while gradually phasing out those with delayed payments or low demand.

7) Profit Margin in Carton Manufacturing

The gross profit margin for corrugated box manufacturing plants typically ranges from 10% to 30%. Factors such as raw material procurement, equipment technology, and workforce structure influence the product’s gross profit margin. To maximize profits and minimize costs:

- Control purchase costs: Material expenses often constitute the majority of total costs. Implement cost-saving measures starting from procurement.

- Supplier management: Establish a robust supplier selection and admission system. Opt for ideal suppliers to ensure smooth production, reduce material wastage, and boost economic benefits.

Remember, cost control in an automatic corrugated box manufacturing plant involves strategic investment in suitable machinery, equipment, and resources based on production needs and business growth stage.

2. 8 Steps to Start a Corrugated Box Manufacturing Plant

Corrugated boxes are incredibly versatile and always in high demand across various industries. In fact, more than 80% of industrial packaging relies on corrugated boxes due to their many benefits. These boxes provide effective cushioning, are lightweight, easy to produce, store, and dispose of, don’t require bundling, offer advertising space, are suitable for export, and are recyclable.

These boxes come in a range of custom sizes and shapes, typically square or rectangular, and are made of corrugated cardboard with different layer specifications like 3-layer, 5-layer, or 7-layer. The process involves sourcing corrugated cardboard from manufacturers or marketplaces and crafting custom boxes to meet clients’ specific needs.

Corrugated boxes find applications in various industries such as beer, glassware, cigarettes, medicines, biscuits, dairy products, cosmetics, clothing, and more. If you’re looking to start a box manufacturing business, here are 8 steps to help you succeed.

1) Learn the Manufacturing Process

To excel in the corrugated box manufacturing industry, it’s crucial to understand the product and the manufacturing process thoroughly. Having a solid grasp of the industry’s nuances is also essential. If you have an educational background in packaging, that’s a plus. Attending seminars on industrial packaging can further enhance your knowledge and skills in this field.

It’s important to be well-versed in which types of boxes are best suited for specific products. This knowledge will not only help you in manufacturing but also in guiding your customers towards the most suitable packaging solutions for their needs.

2) Corrugated Box Manufacturing Business Project Plan

Creating a detailed business plan is crucial for setting up a corrugated box manufacturing plant. While the initial capital required is modest, it’s important to have customized project reports that outline machinery costs, raw material expenses, working capital needs, total investment, and financial projections.

In addition to the financial aspects, defining a clear mission statement for your box manufacturing business is essential. This statement will guide your company’s values and goals. Developing a robust promotional and marketing strategy is also key to reaching your target audience effectively and promoting your products in the competitive market.

3) Corrugated Box Production and Operation License

Before starting your corrugated box manufacturing business, it’s crucial to research and understand the licensing procedures specific to the country where you plan to operate. Make sure to check with the relevant authorities and obtain all the necessary licenses and permits to ensure that your business complies with regulations and operates legally.

4) Corrugated Box Manufacturing Machinery

When setting up a corrugated box manufacturing plant, it’s essential to invest in machinery like corrugators, printing presses, and cutting, and gluing machines. Connect with multiple suppliers to explore your options and find the best equipment for your needs.

Before making a purchase, research customer feedback on the machine companies to ensure reliability and quality. Additionally, verify the warranty period of the machines to safeguard your investment and ensure smooth operations in your manufacturing plant.

5) How Much is the Box Machine?

To produce boxes on a commercial scale, investing in semi-automatic or fully automatic machines is essential. Automated machines are preferred for larger operations due to their efficiency. Prices for good quality machines typically start at $4500.

If you’re looking to purchase a box-making machine, you can request a quote for free on the Alibaba Marketplace. For small businesses in need of an automated box-making machine, feel free to reach out to us for a quote. We’d be happy to provide you with the information you need to get started.

6) What is the Profit Margin?

The profit margin for traditional packaging boxes typically hovers around 5% of the turnover. However, by introducing innovative designs and enhancing the quality of the boxes, it’s possible to increase this margin and improve overall profitability. Investing in creativity and superior craftsmanship can set your products apart in the market and attract customers willing to pay a premium for unique and high-quality packaging solutions.

7) Box Raw Material

The key raw material for corrugated box manufacturing plants is kraft paper, which plays a crucial role in determining the quality of the boxes produced. It’s essential to source high-quality kraft paper from reliable suppliers to ensure the durability and strength of the boxes.

In addition to kraft paper, other raw materials required include glue and stitching materials like needles and thread. These components are essential for assembling the boxes securely.

There are various types of corrugated boxes that can be customized to meet specific customer requirements. These include ordinary corrugated boxes, export-quality corrugated boxes, cartons, cardboard boxes, printed cartons, silver-plated corrugated boxes, and more. By offering a range of customization options, you can cater to diverse customer needs and preferences in the packaging industry.

8) Develop a Promotion Plan

To successfully market your corrugated boxes, start by identifying potential buyers within the industry and reaching out to them with your product catalog. Offer attractive business deals and showcase the quality and design capabilities of your boxes to stand out in the market.

Registering on popular B2B portals and creating an online showcase for your paper packaging business can help expand your reach and attract more customers. Focus on the design aspect of your boxes to create visually appealing packaging solutions that catch the eye of buyers.

Participating in trade shows, business fairs, and local trade associations can also provide valuable networking opportunities and help establish your brand presence in the industry. By actively engaging with potential buyers and showcasing the unique selling points of your corrugated boxes, you can effectively grow your customer base and drive business growth.

3. Conclusion

Starting a corrugated box manufacturing plant can be a lucrative venture for entrepreneurs with expertise in commercial packaging and the paper industry. By carefully considering the necessary preparations—from acquiring the required qualifications and securing an appropriate venue to investing in the right machinery and workforce—you can set the foundation for a successful operation. Understanding the manufacturing process, obtaining the proper licenses, and developing a solid business plan are crucial first steps.

By consistently focusing on quality, maintaining good supplier relationships, and executing effective marketing strategies, you can position your business to meet the growing demand for corrugated boxes across various industries. With thoughtful planning and diligent execution, your small-scale box manufacturing business can thrive in this competitive market, ensuring a steady stream of profits and opportunities for expansion.

How useful was this post?

Click on a star to rate it!

Average rating 0 / 5. Vote count: 0

No votes so far! Be the first to rate this post.

2 thoughts on “How to Start a Corrugated Box Manufacturing Plant?”

Face paper corrugation machine

Board cutters

Sheet pasting machine

Sheet pressing machine

Bar rotatory cutting and creasing machine

Eccentric slotted machine

Stitching machine

அட்டை பெட்டி தொழில் தொடங்க

ஆர்வம்மாக இருக்கிறோம்