Corrugated cardboard packaging is a versatile and cost-effective way to protect, preserve and transport a wide variety of products. The properties of corrugated boards, such as light weight, biodegradability, and recyclability, make them an integral part of the packaging industry. In recent years, the e-commerce industry has become an important player. Well-known e-commerce companies, such as Amazon, have been using corrugated cardboard boxes as their primary packaging.

Corrugated cardboard is very versatile. Therefore, it can take a different form than a box. It is slowly replacing flexible plastic bags due to sustainability concerns. In addition, corrugated boxes are the perfect basis for several printing techniques. Therefore, companies often prefer corrugated packaging as a marketing tool. They also act as mobile billboards, and companies don’t have to spend extra money on marketing.

Due to people’s busy lifestyles, the demand for convenience foods is on the rise. Since corrugated cardboard packaging is moisture-resistant and can withstand long shipping times, companies are increasingly adopting this packaging type to provide better results for their customers. Processed foods such as bread, meat, and other perishable items require these packaging materials to be used only once, thus driving demand.

In addition, the advantages of corrugated cardboard packaging mainly come from its biodegradable properties. Suppliers that switch to other packaging solutions face backlash from consumers. In 2019, Amazon faced backlash from consumers when it switched from corrugated cardboard to foam packaging. The survey conducted by the US “green-blue” found that 65% of respondents are extremely concerned about plastic packaging.

Here we summarize this faq guide for corrugated cardboard to help your packaging business:

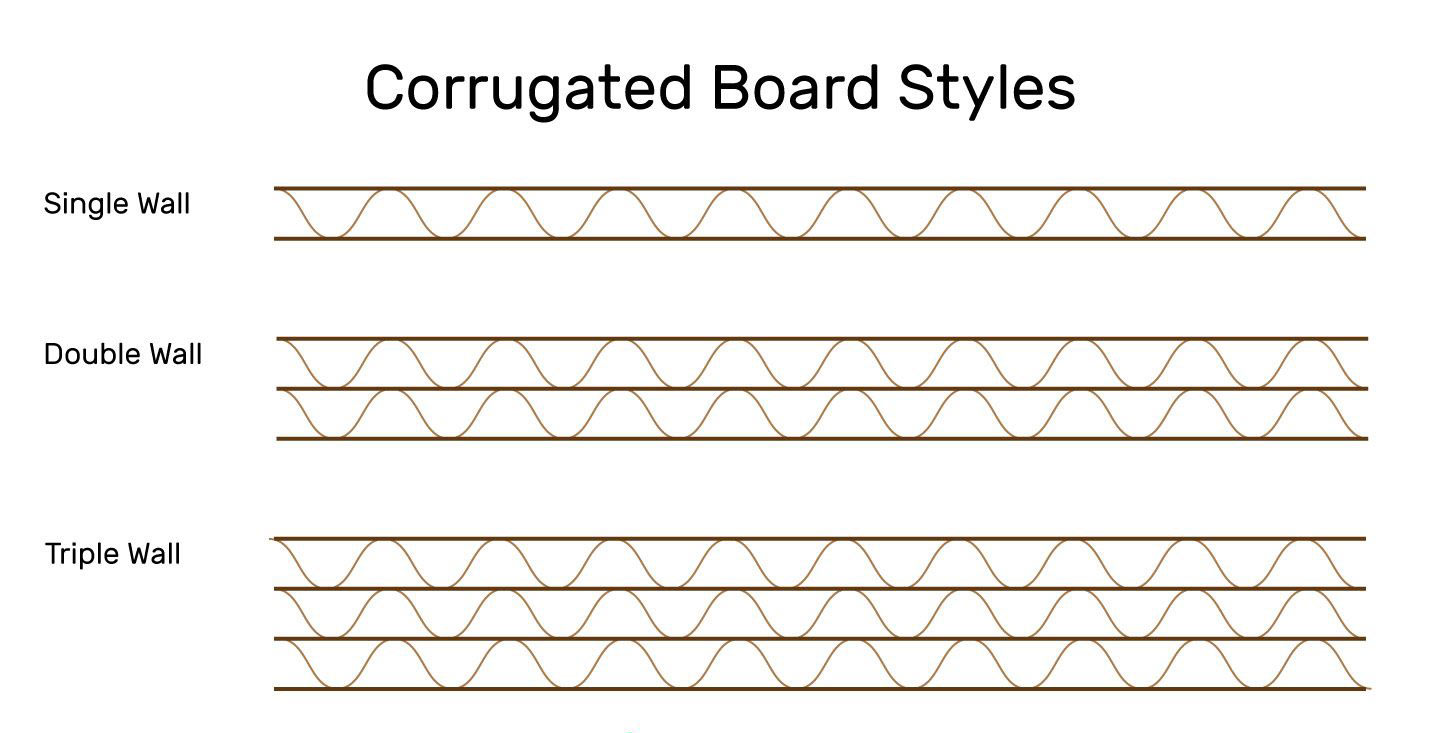

2. Corrugated Board Style

All corrugated cardboard has one layer of corrugated cardboard and at least one layer of liner. Slots and liners can be combined into different layers to form different types. The following are the types of corrugated cardboard commonly used in packaging and transportation:

1) Single-sided Cardboard

The single panel has only two layers of lining layer and a corrugated layer. It’s not as durable as other types of corrugated cardboard but is often used inside boxes to add extra cushioning.

Uses Indoor packaging.

2) Single Wall

Single-ply wallboard is the most common type of corrugated board. If someone is talking about corrugated cardboard, they are probably referring to this style. It consists of two outer layers and a middle layer of corrugated medium.

Uses Transport cartons.

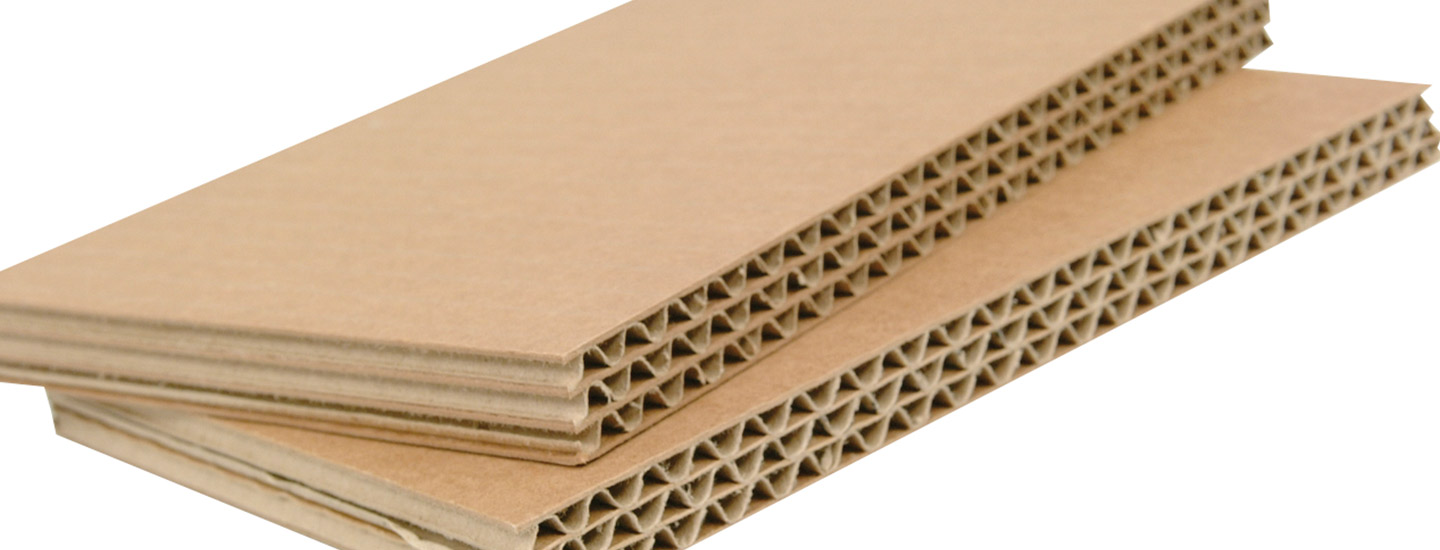

3) Double Wall

Double wall panels consist of two layers of corrugated grooves and three layers of lining, which are very durable.

Application: Industrial carton.

4) Triple Wall

Sturdy three-ply wall panels that can be used in place of wooden boxes. Three layers of grooves make this corrugated board a reliable choice for shipping chemicals or items that require special handling.

Uses Transport crates, and chemical containers.

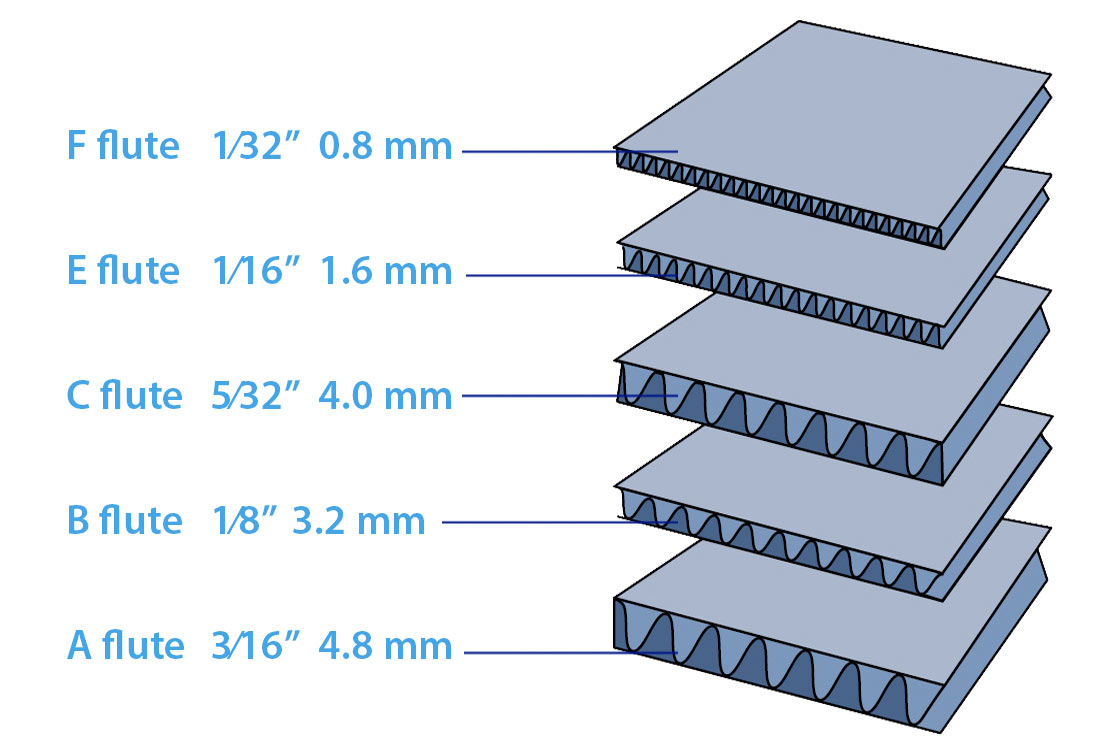

3. Types of Corrugated Flute

Different types of corrugated boxes are designated by the letters A, B, C, E, and f. The most commonly used flute is the C flute, and 80% of cardboard and cartons are composed of this name. The flute’s letter name does not correspond to the size of the corrugated box, but the order in which the flute was invented.

Note: Measurements are approximate. Manufacturers of flutes may vary slightly in size.

1) A flute Corrugated

Type A cardboard has good compression resistance, cushioning properties, and good stacking strength. It is great for wrapping fragile items and is often used for structural strength.

- # of Flutes / Linear Foot: 36

- Flute Height: 1/4”

2) B flute Corrugated

Type B cardboard has excellent compression and puncture resistance, and is a good printing surface. This type of paperboard is often used for inner packaging components such as liners and separators.

- # of Flutes / Linear Foot: 49

- Flute Height: 1/8”

3) C flute Corrugated

Type C cardboard is a good printing surface. It also has compressive and compression properties. It is most commonly used for transporting boxes and securing glass, furniture, food, etc.

- # of Flutes / Linear Foot: 41

- Flute Height: 11/64”

4) E flute Corrugated

The E-type cardboard structure is thinner, which is beneficial to reduce storage space. It has excellent compression resistance and a special printing surface. Commonly used in the packaging of consumer products such as displays, pizza boxes, ballot boxes, glass, ceramics, cosmetics, etc.

- # of Flutes / Linear Foot: 90

- Flute Height: 1/16”

5) F flute Corrugated

F-type paperboard has an excellent printing surface and excellent compression resistance. Its thin construction allows for a stiffer box and fewer fibers. Commonly used in fast food flip-top containers and packaging of consumer goods such as cosmetics, jewelry, and shoes.

- # of Flutes / Linear Foot: 128

- Flute Height: 1/32”

4. Corrugated cardboard for the Anybox box making machine

Here is the main requirement for Anybox box making machine:

Type of corrugated board: thin board or fan shape (single layer, double layer).

- Cardboard thickness: 2-10mm.

- Cardboard Density Range: Up to 1200 GSM.

- Max. Board size: 2500mm width is not limited by length.

- Minimum board size: 200mm wide and 650mm long.

5. The benefits of corrugated packaging

The popularity of corrugated boards and corrugated boxes is due to the many benefits they offer and their relatively low production costs. Here are some of the main reasons for their popularity:

- Protection: Corrugated is one of the best packaging options for those looking to protect their items in transit. It can handle the impact of moving and shipping and can provide a lot of support to avoid buffer damage.

- Durability: Corrugated boxes are durable due to their protective properties. The box itself can take a lot of shock without damaging the product inside, and it also acts as a barrier to the product. One of my clients is a smart lock supplier. You know, a smart lock is a smart device. In the process of transportation must ensure that its parts are not damaged. So corrugated boxes are the best choice.

- Environmentally friendly: Sustainability is becoming more and more important, and packaging is especially important. Corrugated boxes are made from recycled fibers. They are also easy to recycle, making them a better contender for sustainable packaging.

- Customizable: Boxes of different specifications can be easily processed, making on-demand production boxes more efficient and convenient. It is also the most suitable packaging material for printing.

6. How to start a Corrugated Cardboard Packaging Business?

To start a corrugated box manufacturing business, we will give you the following information on how to start a carton box business.

1) Market

Corrugated boxes are mostly used in companies that need to pack materials. You can find their uses in the pharmaceutical, soap, biscuits, cosmetics, tea and coffee, socks, and footwear industries.

About 80% of industrial packaging is done in corrugated boxes because they are very light, easy to store, easy to handle (ie, recyclable), and therefore, are environmentally friendly. Due to their low price, they are widely used in various industries that require product packaging. Amazon and Flipkart use these boxes heavily.

The benefits of corrugated carton boxes over other packaging materials are:

- protect the product;

- Highly customizable;

- very cost-effective and sustainable;

- It is completely recyclable in nature, etc.

Carton boxes are available in different sizes and shapes, usually rectangular and square in shape. There are three layers, five layers, seven layers, and so on.

2) Corrugated cardboard production process

Let’s take a look at the production process of corrugated cardboard.

First, wood chips are made into pulp through a kraft paper process. The trunk is the raw material for making corrugated cardboard. Pine is the most suitable tree species for kraft paper processing. It is then treated with sulfate and broken down into a fibrous pulp. The kraft paper roll is then inserted into the corrugator.

The kraft paper is then heated, pressurized, and glued. The result is a continuous sheet of cardboard, called a box blank. The cardboard is then cut into wide frame blanks according to the template design. Other processes are also applied such as cutting, gluing, and printing on boxes.

This is how corrugated cardboard is made.

3) Marketing

You should buy high-quality raw materials to ensure the quality of the product. Try to be as direct as possible to companies that require corrugated box packaging. You can focus on industries like pharmaceuticals, food processing, and e-commerce, and as we mentioned before, they have very high demands for these cartons.

You can list your business on popular B2B portals like Tradeindia and Indiamart, just dial up as this can help you in generating your business leads. Don’t miss trade fairs and trade fairs dedicated to the paper and packaging industry, such as PackPlus, PackExIndia, Paperex, and more. You should read publications related to this industry to keep yourself up to date on what’s happening in and around the packaging industry.

7. What is the market demand for the cardboard box business?

The primary market demand for corrugated box manufacturing enterprises is packaging and cargo transportation. All products require a corrugated box for the same shipping.

Big companies like Sony, LG, Samsung, etc. have their own box manufacturing companies. But small companies such as toilet paper manufacturers, fruit and vegetable exporters, churches, electrical products, etc. Does not have its own corrugated box manufacturing company. So the huge market is there.

8. What is the future of the cardboard box business?

The latest data on the global containerboard and corrugated packaging market show that by 2020, the consumption of corrugated packaging will reach 160.5 million tons, valued at $170.7 billion.

According to expert analysis, from 2020 to 2025, the global corrugated board will grow at a compound annual growth rate (CAGR) of 3.8%, reaching 205.7 billion US dollars. In that year, global cardboard consumption will grow at a slightly slower rate, reaching 193.2 million tonnes.

A study tracks micro and macro trends in the industry from 2015-2025. This is divided into six levels of corrugation – Unbleached Cowhide Liner (UBKL), White Top Cowhide Liner (WTKL), Unbleached Test Liner (UBTL), White Top Test Liner (WTTL), Semi-Chemical Tank (SCF), Waste-Based Tanks (WBF); 15 end-use applications; 63 countries and world regions.

The COVID-19 pandemic will have a significant impact on corrugated paper consumption in certain industries and regions, especially those hardest hit by the virus. In end-use food, shipments will be the least affected, while other consumer goods will see a more pronounced decline.

In developed regions, strong growth in e-commerce will alleviate these problems as stay-at-home consumers take on more online shopping. Several board converters have developed e-commerce-specific delivery designs to take advantage of this, underscoring what industries have been identified as key growth sectors.

Expert analysis has identified the following key business trends that will support the further use of corrugated cardboard packaging in the long run.

- Recycling and sustainability will remain key issues for converters and brand owners, but the oversupply of materials could create new price pressures.

- Demand for finer flute grades and higher quality print cases will rise.

- Further increased pressure on corrugated design for lightweight will have a negative impact on sales.

- E-commerce will continue to grow.

- Especially high-quality printed graphics.

- Dimension to minimize the weight of packaging and outer protective components (DIM) will slow some of the expanded use of ripple in direct-to-consumer e-commerce shipping.

- Digital printing will increase the overall demand for premium substrates and expand the choice of packaging printers in standard and RRP corrugated formats.

- Coated corrugated grades will become more recyclable with the development of new coating technologies, including bio-based polymer solutions.

- Industry consolidation will continue to lead to greater concentration of capabilities and greater uniformity of users.

9. How will the Corrugated Cardboard Packaging Business change this year?

Absolutely, the corrugated cardboard packaging business is changing this world, here are some main changes this year:

1) Changes in the industry

The demand for corrugated packaging is expected to decline in the near future, according to many packaging experts. However, thanks to recent technological advancements such as e-commerce, we are now seeing the opposite. Adapting to these changes will be critical in the coming years.

2) Growth of corrugated packaging

Continued industrialization in countries such as China and Brazil is expected to continue to drive economic growth, even as many packaging plants have moved overseas and tariffs are rising. Products have become more diverse and delivery options more advanced, which means unique boxes and materials are required to package and protect merchandise. The packaging industry continues to grow despite the rising prices of markers.

3) E-commerce increases

In the wake of the COVID-19 pandemic, the demand for e-commerce packaging and shipping solutions has increased dramatically. E-commerce sales are expected to exceed $5.5 trillion over the next three years, a huge boon for brands smart enough to catch up with e-commerce growth. This will significantly impact the demand for corrugated boxes, which already meet 80% of e-commerce demand.

4) Corrugated packaging trends

Growth in demand for corrugated and e-commerce packaging isn’t the only change from this year and beyond. Emerging trends including sustainable packaging and aesthetic packaging continue to drive the corrugated packaging industry.

5) Attractive packaging

Aesthetics have always been important, but their value is increasing as capturing the attention of potential clients becomes more challenging. Especially when it comes to visually-driven products like carefully packaged subscription boxes, it’s also important to consider the growing influence of social media interactions.

6) Smart devices, smart packaging

Advances in technology lead to the development of the corrugated packaging industry, along with market changes and packaging trends. Is your company capable of adapting to evolving packaging needs, or willing to offer new services to capture this expanding business?

How useful was this post?

Click on a star to rate it!

Average rating 5 / 5. Vote count: 1

No votes so far! Be the first to rate this post.

1 thought on “An Ultimate FAQ Guide for Corrugated Cardboard Packaging Business”

Thanks…It’s a lovely note. this is more helpful to understand more about a corrugated cardboard packaging business. I love the information I have gathered here, thanks so much, and keep up the good work. It has helped me.